Manhole covers, often hidden beneath our feet, play a crucial role in urban infrastructure. They provide access to underground utility systems like sewers, storm drains, and telecommunications networks. These unassuming metal plates serve an essential purpose in maintaining our cities and communities. In this comprehensive blog, we’ll dive deep into the world of manhole covers, with a particular focus on the advantages of Ductile Iron Manhole Covers offered by Travis Perkins. We’ll also address common questions like why manhole covers aren’t galvanized, what happens if you drop fireworks into a manhole, and how to choose the right manhole cover. Let’s begin our journey underground welcome to the fascinating realm of manhole covers! Often overlooked in the hustle and bustle of urban life, these seemingly mundane fixtures actually hold a wealth of history, artistry, and engineering significance.

Understanding the World of Manhole Covers

Manhole covers, also known as access covers or utility hole covers, are typically circular or rectangular metal plates that are installed in roadways, sidewalks, and other public areas. These covers provide access to various underground utility systems, making maintenance, inspections, and repairs possible. They come in different materials, with Ductile Iron being a popular choice due to its remarkable advantages.

What benefits does a ductile manhole cover offer?

Ductile Iron Manhole Covers, like those offered by Travis Perkins, bring a host of benefits to the table, making them an ideal choice for urban infrastructure. Let’s explore these advantages:

1. Durability and Strength

Ductile Iron is renowned for its exceptional durability and strength, ensuring that manhole covers can withstand heavy loads, vehicular traffic, and harsh environmental conditions.

These covers are less prone to cracking or breaking compared to traditional cast iron covers, offering long-lasting performance.

2. Corrosion Resistance

Ductile Iron Manhole Covers are naturally resistant to corrosion, which is a common issue with other materials. This resistance extends their lifespan and reduces maintenance costs.

3. Safety

These covers are designed with safety in mind. They are slip-resistant, reducing the risk of accidents, especially in wet or icy conditions.

The anti-theft locking systems provided by Travis Perkins enhance security by preventing unauthorized access.

4. Versatility

Ductile Iron Manhole Covers are suitable for various applications, including pedestrian areas, roadways, and commercial spaces.

They are available in different sizes and load-bearing capacities, allowing you to choose the right cover for your specific needs.

5. Environmental Friendliness

Ductile Iron is a recyclable material, making these manhole covers an environmentally responsible choice.

Best Manhole Cover available on Travis Perkins:

1. Clark-Drain dual locking polypropylene inspection chamber cover and frame driveway 450mm diameter

The Clark-Drain 450mm diameter manhole cover and frame, constructed from durable polypropylene, boasts a robust 35kN load rating classification, making it suitable for driveway applications. This versatile cover, which includes the frame, is compatible with shallow inspection chambers from major manufacturers, offering convenience and flexibility. Its slip-resistant tread pattern enhances safety, and its eco-friendly construction from recycled materials aligns with sustainable practices. Additionally, the dual locking mechanism ensures secure and reliable performance.

2. Clark-Drain inspection chamber cover and frame ductile iron 450mm diameter

The Clark-Drain 450mm diameter circular manhole cover and frame, made from robust ductile iron, boasts a B125 load rating classification, indicating its ability to withstand significant loads. It features integral lifting keyholes for convenient access, and it’s BSI Kitemark certified to meet the standards set by BS EN 124. This cover is specifically designed to fit a 450mm inspection chamber, making it a reliable choice for various applications.

3. Clark-drain manhole cover & frame ductile iron 600mm x 600mm

The Clark-Drain 600 x 600mm manhole cover and frame, constructed from durable ductile iron, carries a D400 load rating classification, making it ideal for high-traffic zones like highways and commercial/industrial areas. This cover complies with HA104/09 regulations for low-risk areas and features a Double-Tri non-rock design for stability. It is accredited by BS EN124 and bears the Class D400 rating, signifying its capacity to handle substantial loads of up to 40 tons. Additionally, integral lifting keyholes and Kitemark certification ensure convenience and quality.

4. Clark-Drain manhole cover and frame ductile iron 450mm x 600mm

The Clark-Drain 600 x 450mm manhole cover and frame, crafted from robust ductile iron, carries a B125 load rating classification, making it suitable for pavement, driveways, and precinct areas. It meets the B125 loading class standards set by BS EN124 and includes a frame for added convenience. Featuring a slide-out access design and a unique corner design to ensure proper cover orientation, this product also comes with integral lifting keyholes for easy handling. Its Kitemark certification assures quality and reliability.

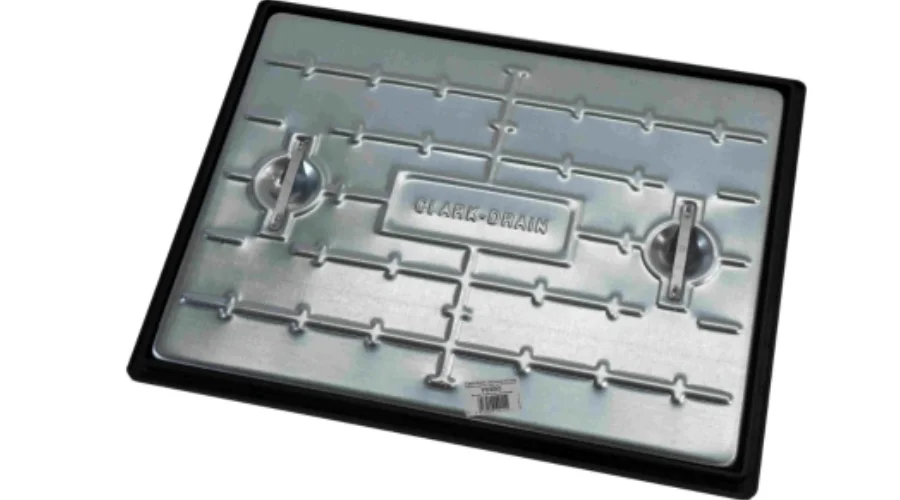

5. Clark-Drain manhole cover and frame galvanised steel 450mm x 600mm 5 tonne

The Clark-Drain 600 x 450mm manhole cover, featuring galvanized steel construction and a polypropylene frame, offers a 5-tonne GPW load rating classification, making it well-suited for domestic driveway applications. It comes equipped with two integral lifting handles for effortless access and includes a frame for added convenience. With a solid top design, this cover ensures reliable performance under a 5-ton GPW loading capacity.

Exploring Common Manhole Cover Myths:

Now that we’ve delved into the advantages of Ductile Iron Manhole Covers, let’s address some common myths and questions about manhole covers:

1. Why Aren’t Manhole Covers Galvanized?

Manhole covers are typically not galvanized due to several reasons:

- Galvanizing involves applying a zinc coating to iron or steel to prevent corrosion. However, Ductile Iron already possesses inherent corrosion resistance, making galvanization unnecessary.

- The additional weight from galvanization can exceed allowable limits for manhole covers, affecting their load-bearing capacity.

2. Why does a manhole explode if you drop fireworks in it?

While it might seem like a scene from a Hollywood movie, manhole explosions can occur due to a buildup of flammable gases in the sewer system. Dropping fireworks or other ignition sources into a manhole can ignite these gases, resulting in an explosion. It’s essential to exercise caution around manholes and report any suspicious odors or conditions to local authorities.

Navigating the World of Manhole Covers:

1. Opening and closing a sewer grate or manhole cover:

Opening and closing a manhole cover requires proper equipment and techniques:

- Use a manhole cover lifter or hook to safely lift the cover without straining your back.

- Ensure the area around the manhole is clear of obstacles.

- Slowly and carefully lift the cover, taking note of any potential hazards below.

- When closing the cover, lower it gently and secure it in place to prevent accidents.

2. Height of a Manhole Cover

The height or thickness of a manhole cover can vary depending on its intended use and load-bearing capacity. Standard manhole covers typically range from 3 to 4 inches in thickness. However, covers designed for heavy-duty applications may be thicker to support greater loads.

3. Manhole Covers in Street Vs. Manhole Covers in grass

Manhole covers are typically located in the street rather than in grassy areas for several reasons:

- Accessibility: Placing manhole covers in the street ensures easy access for maintenance and repairs.

- Safety: Street-level covers are less likely to be obstructed by vegetation or debris, reducing the risk of accidents.

- Utility Placement: Manholes are strategically positioned to provide access to underground utility systems, and these systems are often located beneath roadways.

4. Choosing the right manhole cover

Selecting the appropriate manhole cover involves considering several factors:

- Load-Bearing Capacity: Determine the maximum load the cover needs to support, including vehicular traffic if applicable.

- Size: Measure the dimensions of the access point to ensure a proper fit.

- Material: Choose a material that suits the environment and load requirements. Ductile Iron is an excellent choice for its durability and corrosion resistance.

- Safety Features: Consider features like slip resistance and anti-theft locking systems to enhance safety and security.

Conclusion

Manhole covers may go unnoticed in our daily lives, but they are essential components of our urban infrastructure. Ductile Iron Manhole Covers, such as those offered by Travis Perkins, brings a wealth of advantages, from durability and corrosion resistance to safety and versatility. Understanding their benefits and dispelling common myths helps us appreciate the critical role these covers play in maintaining our cities. Whether you’re a construction professional, municipal worker, or a curious reader, we hope this comprehensive guide sheds light on the world beneath our feet and the valuable contributions of manhole covers to our communities. For more information, visit Xprrtupdates.